It is known that adding water to silicon creates hydrogen through oxidation – but now scientists have discovered that by using silicon nanoparticles, this process is much faster than they had expected. By using particles 10 nm across, hydrogen was generated 150 times faster than when particles of size 100nm were used. All of this happens without any additional input heat light or electricity.

This is a very important discovery as hydrogen is to be used as a major method to help deliver energy for many applications. It is imperative that we find a fast, efficient and inexpensive way to obtain this resource. As opposed to electrolysis, which requires other materials such as zinc, silicon, aluminum and energy input, the use of these nanoparticles is far more efficient and less costly.

Before the consideration of silicon nanoparticles, the silicon-water oxidation technique was proven to be slower and performed poorly compared to electrolysis. On the other hand, silicon is abundant, easy to transport and it has a high energy density. Theoretically it produces two moles of hydrogen per one mole of itself. Of course, the silicon in discussion is silicon in bulk – what would happen if the surface area of each particle were increased? That is, would the performance of silicon nanoparticles be better than silicon in bulk? After experimentation, the benefits of using these nanoparticles are now obvious.

Mark Swihart, co-author and Professor of Chemical and Biological engineering at the University of Buffalo says, “I believe the greatest significance of this work is the demonstration that silicon can react with water rapidly enough to be of practical use for on-demand hydrogen generation. This result was both unexpected and of potential practical importance. While I do not believe that oxidation of silicon nanoparticles will become feasible for large scale hydrogen generation any time soon, this process could be quite interesting for small – scale portable applications where water is available”.

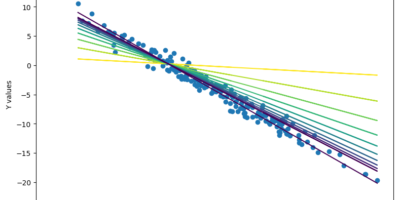

The performance of 10nm particles provides such a large improvement that it actually exceeds the expected performance rate for the particles. The 10nm particles performed six times better than their 100nm counterpart. In order to explain this strange phenomenon, the scientists focused their attention to the etching process which produced these particles. When the 10nm particles were etched, they were subject to isotropic etching whereas the 100nm particles underwent anisotropic etching. This means that the lattice planes in the 10nm particles were etched in an equal amount in each direction whereas the 100nm particles underwent a slightly less uniform plane-etching process. Thus, the smaller particles were able to expose more of each facet in comparison and ultimately have a much higher surface area for reaction. In addition, the larger (100nm) silicon particles have more layers in which oxidized silicon by products may be produced, which makes it harder for water to react with the layers.

After this advancement, it is no longer possible to dismiss the possibility of using silicon as a potential method for the production of hydrogen fuel. Who knows, we may one day see the use of these nanoparticles in the main fuel cells of “clean” cars or better yet- at the heart of the energy grid for a metropolis!

Leave a Reply